Infrared thermometers measure surface temperatures using infrared energy, offering non-contact convenience. They feature laser targeting, data storage, and are widely used in medical and industrial applications for accurate readings.

Overview of Infrared Thermometer Technology

Infrared thermometers use advanced optics to detect infrared radiation emitted by objects, converting it into precise temperature readings. Equipped with features like laser targeting, adjustable emissivity, and data storage, these devices ensure accurate measurements. They operate non-contact, making them ideal for safety in hazardous environments. Built-in sensors and digital processors enable rapid response times, while LCD displays provide clear results. Designed for versatility, they cater to medical, industrial, and HVAC applications, offering reliable performance across various settings.

Importance of Reading the Instruction Manual

Reading the instruction manual is crucial for safe and effective use of infrared thermometers. It provides essential safety precautions, such as avoiding direct laser exposure to eyes and proper cleaning methods. Understanding operational procedures ensures accurate temperature readings and prolongs the device’s lifespan. The manual also explains advanced features like emissivity adjustment and data storage. Adhering to guidelines helps prevent errors and potential damage, ensuring reliable performance in medical, industrial, and HVAC applications. Proper usage techniques are vital for obtaining precise measurements consistently.

Product Features and Technical Specifications

Infrared thermometers feature advanced specs like laser targeting, adjustable emissivity, and wide temperature ranges. They include data storage, auto power-off, and NIST-traceable calibration for high accuracy and reliability.

Key Features of Infrared Thermometers

Infrared thermometers offer advanced features like laser targeting for precise aim, adjustable emissivity for accuracy, and data storage for recording measurements. Many models include temperature alarms, Min/Max readings, and auto power-off for efficiency. They often feature NIST-traceable calibration, ensuring reliability and compliance with standards. Some thermometers allow switching between Fahrenheit and Celsius, while others include LCD displays with backlight for visibility in dark environments. These devices are designed for non-contact measurements, making them ideal for medical, industrial, and HVAC applications, providing quick and accurate temperature readings without physical contact.

Technical Specifications and Measurement Ranges

Infrared thermometers typically measure temperatures from -32°F to 535°F (-35°C to 280°C) with a distance-to-spot ratio of 10:1 or 12:1. They often feature response times under one second and accuracy within ±1.5%. Some models include adjustable emissivity settings, while others offer humidity tolerance up to 85% and operating altitudes up to 6562 feet; Laser classification for eye safety is typically Class II with <1mW power, ensuring safe operation across various environments, from indoor to outdoor applications, providing reliable and consistent performance.

Safety Information and Precautions

Avoid exposing the thermometer to water or extreme conditions. Handle optics carefully to prevent damage. Store safely out of children’s reach. Ensure eye protection when using laser features and always follow manual guidelines for safe operation.

General Safety Guidelines for Use

Always handle the infrared thermometer with care to avoid damage. Avoid exposing the device to water, extreme temperatures, or harsh environments. Ensure the lens is clean and free from obstructions. Never point the laser directly at eyes or reflective surfaces. Operate the thermometer in stable conditions, maintaining a safe distance from hot or hazardous objects. Keep the device out of reach of children. Regularly inspect for damage and replace worn or damaged parts. Follow all instructions in the manual for safe and accurate measurements.

Specific Warnings and Cautions

Do not immerse the thermometer in water or expose it to direct sunlight. Avoid using the device near flammable materials. Never modify or repair the thermometer yourself. Keep the laser away from eyes and reflective surfaces. Ensure the target area is clear of obstructions. Do not measure temperatures through glass or transparent surfaces. Always calibrate the device as instructed. Use only recommended batteries and avoid overcharging. Store the thermometer in a dry, cool place when not in use. Adhere to all safety guidelines for accurate and reliable results.

Operating Instructions and Measurement Techniques

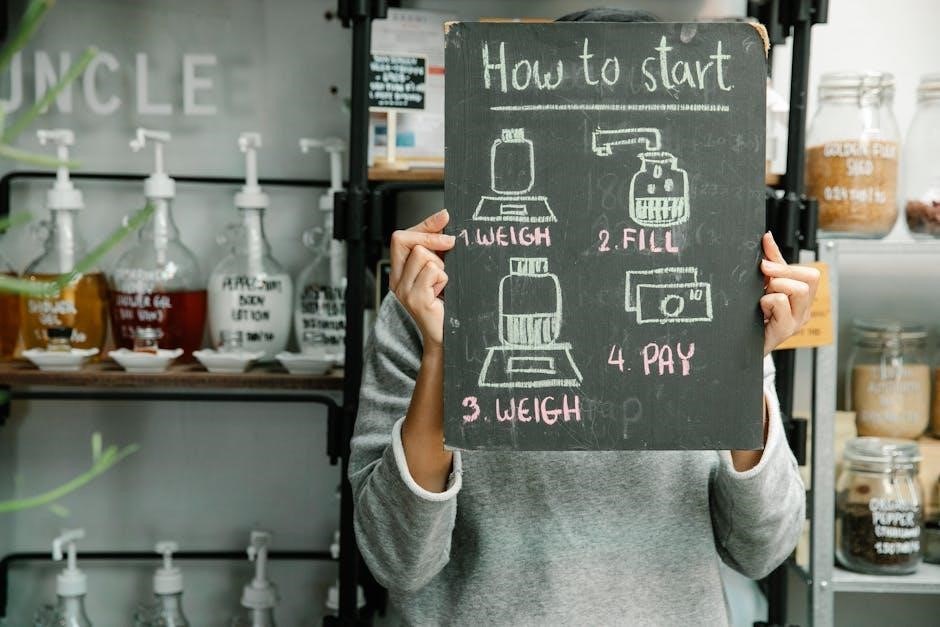

Operating an infrared thermometer involves aiming the laser, pulling the trigger to activate, ensuring stable environmental conditions, and storing readings for future reference.

Step-by-Step Guide to Using the Thermometer

Ensure the thermometer is calibrated and ready for use.

Power on the device by gently pulling the trigger.

Aim the laser pointer at the target surface or forehead.

Maintain the recommended distance-to-spot ratio for accuracy.

Hold the trigger to capture the temperature reading.

Store the measurement using the data hold function if needed.

Turn off the device after use to conserve battery life.

Refer to the manual for specific settings like emissivity adjustment.

Best Practices for Accurate Measurements

- Ensure the thermometer’s sensor is clean and free from obstructions.

- Avoid measuring surfaces with high reflectivity or uneven emissivity.

- Maintain the recommended distance-to-spot ratio for precise readings.

- Account for environmental factors like ambient temperature and humidity.

- Calibrate the device regularly and adjust emissivity settings as needed.

- Stabilize the environment to prevent sudden temperature fluctuations.

- Use the laser guide to focus accurately on the target area.

- Avoid direct sunlight or heat sources that could interfere with readings.

Calibration and Maintenance

Calibrate the infrared thermometer using a black body source for accuracy. Regularly clean the sensor and check batteries. Follow manual guidelines for long-term performance and reliability.

How to Calibrate the Infrared Thermometer

Calibration ensures accurate measurements. Use a NIST-traceable black body source. Set the thermometer to the correct emissivity. Compare displayed readings with the known temperature. Adjust offset if necessary. Refer to the manual for specific steps. Regular calibration maintains precision. Follow manufacturer guidelines for optimal performance and reliability.

Maintenance Tips for Long-Term Accuracy

Regular cleaning of the lens with a soft cloth ensures clear infrared transmission. Avoid exposure to harsh chemicals or extreme temperatures. Store the thermometer in a dry, protective case. Replace batteries as needed and ensure proper power management. Periodically check for firmware updates. Handle the device with care to prevent physical damage. Follow these steps to maintain optimal performance and extend the lifespan of your infrared thermometer.

Troubleshooting Common Issues

Address inaccurate readings by ensuring clean optics and proper calibration. Check for low battery, faulty laser alignment, or environmental interference. Refer to the manual for reset procedures.

Resolving Error Codes and Malfunctions

Error codes on infrared thermometers often indicate issues like low battery, sensor malfunctions, or calibration errors. Refer to the manual for specific code meanings. Ensure the device is clean and free from environmental interference. If the laser misaligns, adjust it carefully. For persistent problems, reset the device or contact technical support. Always follow the manufacturer’s troubleshooting guide to restore functionality and accuracy. Regular maintenance and calibration can prevent recurring malfunctions.

Addressing Inaccurate Readings

Inaccurate readings on an infrared thermometer can stem from a dirty sensor, environmental interference, or incorrect emissivity settings. Ensure the lens is clean and free of debris. Check for ambient temperature fluctuations or humidity. Verify that the emissivity setting matches the target material. If issues persist, recalibrate the device following the manual’s instructions. Ensure proper distance-to-spot ratio and avoid obstructions. Consult the user manual for troubleshooting steps specific to your model to restore accurate measurements and maintain reliability.

Frequently Asked Questions (FAQs)

Q: How accurate are infrared thermometers? A: Accuracy varies by model but typically ranges from ±1°C to ±2°C. Calibration ensures precise readings.

Q: Can I adjust emissivity settings? A: Yes, most models allow emissivity adjustments for different surfaces, improving measurement accuracy.

Q: Why do readings seem inconsistent? A: Dirty sensors, environmental factors, or incorrect settings can cause inaccuracies. Clean the sensor and check settings.

Q: How do I calibrate my thermometer? A: Refer to the manual for calibration steps, often involving a reference source like ice water or a blackbody calibrator.

Q: Are infrared thermometers waterproof? A: Most are not; avoid immersion in liquids and clean only as instructed.

Clarifying Misconceptions

Some believe infrared thermometers measure internal temperatures, but they only detect surface temperatures. They are not waterproof and should avoid direct contact with liquids. While highly accurate, readings can be affected by environmental factors like humidity or dirty sensors. Calibration is essential for precision. The laser guide aids targeting but should not be directed at eyes. Understanding these limitations ensures proper and safe usage. Always refer to the manual for specific model capabilities and adjustments, such as emissivity settings, to optimize performance and accuracy in various applications.

Compliance and Regulatory Information

Infrared thermometers must comply with FDA, CE, and RoHS standards. Ensure the device meets local regulations and is NIST-traceable for accuracy. Always verify certifications before use.

Standards and Certifications

Infrared thermometers must comply with regulatory standards such as FDA, CE, and RoHS for safety and accuracy. Many models are NIST-traceable, ensuring reliable measurements. Certifications like IEC and ISO guarantee adherence to international quality standards. Laser safety standards, such as Class II, ensure user protection. Environmental compliance is also verified, meeting global regulations. Always check for certifications specific to your region and application to ensure the device meets required standards for industrial, medical, or general use.

Environmental and Safety Compliance

Infrared thermometers comply with environmental regulations such as RoHS and WEEE, ensuring eco-friendly production and disposal. They meet safety standards like IEC 60601 for medical devices and are designed to minimize hazardous materials. Laser Class II certification ensures eye safety, while energy-efficient designs reduce battery consumption. Proper disposal guidelines are provided to promote sustainability. Always follow local regulations and manufacturer instructions for safe use and disposal, contributing to environmental protection and user safety.